DAPAI Mirror Production Workshop

Our professional production line is outfitted with cutting-edge machinery, including Glass Cutting Machines, CNC Automatic Edging Machines, Laser Engraving Machines, Automatic Drilling Machines, Washing and Drying Machines, and Laminating Machines. As a renowned manufacturer, supplier, and factory specializing in wholesale LED mirrors, we ensure each product meets our stringent standards for excellence and innovation.

DAPAI Mirror Injection Molding Workshop

At DAPAI Mirror, our injection molding workshop is equipped with 72 automatic injection molding machines that operate 24 hours a day, ensuring uninterrupted production and timely delivery. This setup allows us to handle diverse projects with varying complexities and material requirements. Our skilled technicians oversee the process, optimizing machine settings for optimal performance and minimal waste. The result is a seamless production line that consistently delivers durable and aesthetically pleasing mirror components to meet the demands of our wholesale clients.

Glass Cutting Machine

The Glass Cutting Machine allows for precise cuts and shapes, ensuring that each mirror produced meets our stringent standards for excellence and design, making it an essential tool in our manufacturing process.

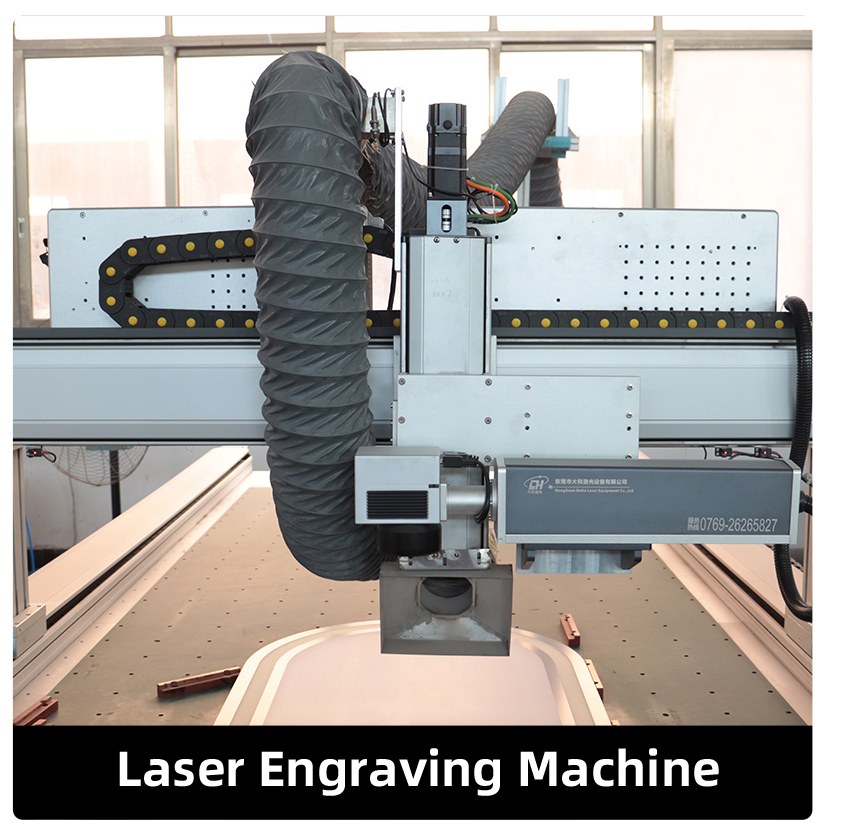

Laser Engraving Machine

Laser Engraving Machine is a state-of-the-art tool that allows us to add intricate and personalized designs to our mirrors. This precise technology ensures that every engraving is clear and detailed, enhancing the aesthetic appeal of our products.

CNC Automatic Edging Machine

The CNC Automatic Edging Machine at DAPAI Mirror represents our commitment to technological advancement and precision. It provides automated, accurate edging, ensuring that every mirror has a polished and refined look, contributing to the high-quality craftsmanship that defines our brand.

Automatic Drilling Machine

Automatic Drilling Machine allowing us to create precise holes in our mirrors with speed and accuracy. This machine ensures that each mirror is perfectly crafted to meet our high standards of quality and functionality.

Washing And Drying Machine

The Washing and Drying Machine is key to maintaining the pristine condition of our mirrors. It uses advanced technology to remove dust and residues, followed by rapid drying to prevent water spots, ensuring that every mirror reflects our commitment to excellence.

Laminating Machine

The Laminating Machine at DAPAI Mirror is essential for producing high-quality mirrors with added longevity. It seamlessly bonds protective layers to the glass, ensuring that each mirror is not only beautiful but also built to last, reflecting our dedication to safety and excellence.

DAPAI Mirror Workshop

At DAPAI Mirror, our state-of-the-art production workshop is the foundation of our success. We employ more than 800 technical experts who bring their craftsmanship to our diverse range of mirrors. Our workshop is divided into dedicated sections for producing makeup mirrors and larger units like bathroom mirrors and Hollywood bulb mirrors. Our commitment to innovation is reflected in our 10 automated production lines and 72 round-the-clock automatic injection molding machines, enabling us to meet the high demands of our clients with unmatched quality.

DAPAI Mirror's Aging Test Workshop and Semi-Finished Product Area

At DAPAI Mirror, we take pride in our robust quality control measures, particularly in our Aging Test Workshop. Here, our products are subjected to comprehensive aging tests, guaranteeing their durability and performance. In tandem, our Semi-Finished Product Area plays a crucial role in our production process, where each component is carefully examined and readied for the next phase of manufacturing. These facilities are testament to our unwavering commitment to providing top-tier mirrors that stand the test of time.

English

English  Spanish

Spanish  Polish

Polish  German

German  Arabic

Arabic  French

French  Russian

Russian